Engineering

Not every start must be hard. Starting a new job may be easier if high-quality engineering is done. This term conceals several separate activities, which, if executed correctly, allow not only to shorten the overall preparation time for the start of implementation but also to make all process more efficient. We design industrial automation with emphasis on functionality, reliability and low costs.

Consultancy

The life cycle of the whole contract usually begins at a negotiating table and continues through the designers' and engineers’ computers to the real implementation. In consulting, we use a long-term experience of our employees, monitoring of new trends in technology and the ability to find new solutions. But this is not all. We bring added value to our customers by many other ways.

We are looking for new solutions and ideas to improve the quality of the entire work.

We conduct studies and analyses of the existing and new projects

- return study — financial balance sheet

- increasing the efficiency of technology

- simplification of the original technical solution

- elaboration of the protocol on the

Design activities

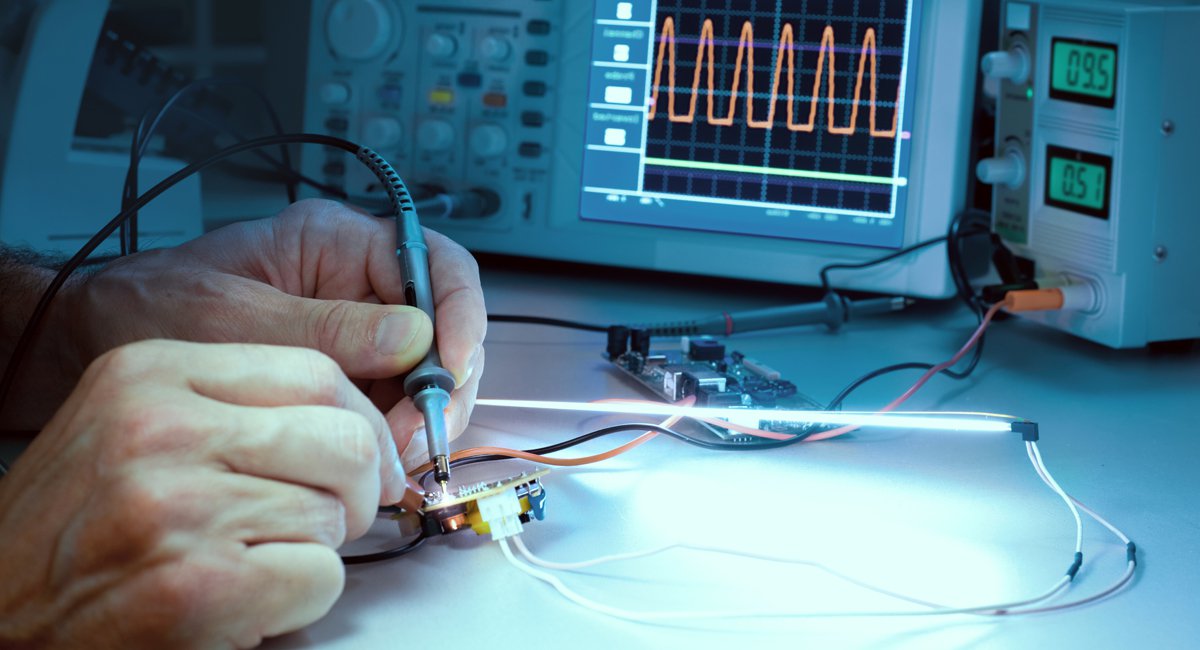

Electro design is an integral part of the complete deliveries of our company. Once the specification, scope and limits of deliveries of the individual parts are precisely defined and agreed, we begin to process the project documentation of the technological wiring.

We supply the project documentation to many customers as a standalone product.

Finished projects are delivered both in printed and electronic form in EPLAN, ELCAD or AutoCAD LT systems according to the customer's request.

Project management

Time is money. That is why we pay a close attention to managing the entire project in accordance with the customer's requirements. We use advanced tools for coordinating the work, deadlines and solving of unexpected situations. We can estimate the key points of the project, observe important deadlines and work according to the agreed timetable.

The usual course of the project is as follows:

- setting goals and resulting parameters, including terms;

- evaluation of the technical options of the device;

- drawing up the project documentation;

- delivery of the electrical material, creation of the control software and visualizations;

- wiring, commissioning and training of the operators.

Studies and analysis of the drives

Based on the machine or technology basis, we can prepare the driver study for our customers. This is a suggestion in which the optimization of electric drives is carried out with regard to the key requirements — price, a method of regulation, requirements for technological parameters, possible torque control, etc.

Based on our experience from previous projects and implementations, we can recommend the most suitable type of electric drive.

The pre-project consultation has already brought considerable financial savings to our customers and has prevented unnecessary expenses.

Applied development

After finishing the implementation of the order, we remain in touch with our customers. We cooperate closely on further development and improving the technical level of existing equipment and instruments to meet the demanding legislation requirements. At the same time, we strive to continuously increase the utility value of our implementations without increasing their cost.

Applied development focuses in particular on the following points:

- optimization of device performance;

- increasing the operational efficiency;

- adaptation to new standards and requirements;

- process automation.

Competence and expertise

In order to maintain the high standard and level of knowledge of our specialists, our employees are regularly trained within their competencies and expertise.

In order to fulfil the legislative requirements in a wide range of technologies, the company owns a number of licenses and certificates.

You can see the most important of them here.

In addition to these obligatory training courses, in according to the arrival of new technologies and products, the in-house expertise increasing and personal experience sharing also take place.